View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More

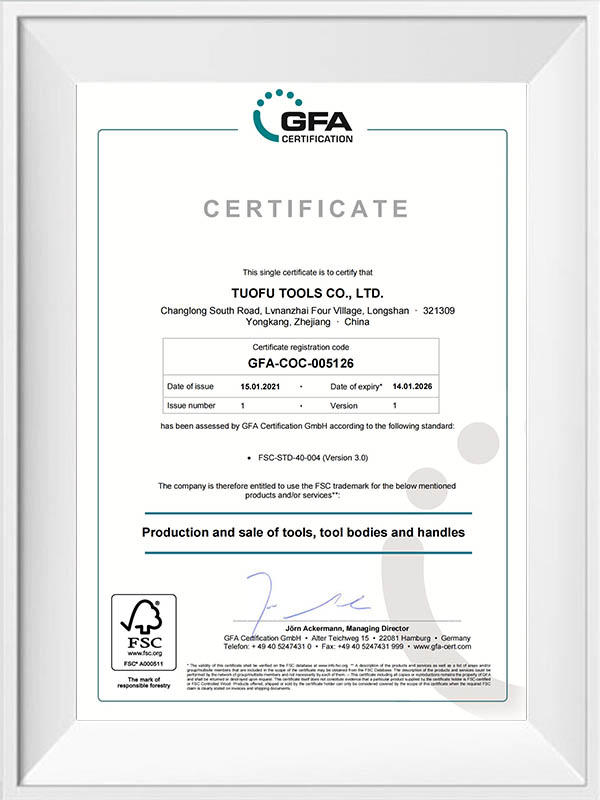

Zhejiang Yongkang Tuofu Tools Co., Ltd. is located in Yongkang, the famous hardware capital in China. It is an enterprise specializing in the production of medium and high-end hardware tools. After years of development, the company has strong independent design and development capabilities, and has the annual production capacity of 20 million pieces of various woodworking tools and carving tools. The products are mainly exported to Europe, Germany, the United States, Russia and Japan. and other countries and regions. The product quality is stable, the benefits are remarkable, and are well received by users. The company always strictly implements the requirements of the GS quality system standard, and always adheres to the principle of "quality first" in production. After 20 years of hard work, the product quality has reached the domestic advanced level.

Woodturning is a skill that requires not only creativity but also the right tool...

View MoreIn recent years, woodworking has evolved from a traditional craft into a popular...

View MoreHaving the right tools is essential for precision and ease. Among the wide range...

View MoreHaving the right tools is crucial for achieving quality results. An increasingly...

View MoreWoodcarving is an intricate craft that requires precision, skill, and the right ...

View MoreAdvantages of Interchangeable Head Turning Tool Sets:

Versatility: Interchangeable head turning tool sets are designed to accommodate a variety of machining tasks. They come equipped with different cutting inserts and toolholders, allowing manufacturers to perform multiple operations with a single tool set. This versatility reduces the need for numerous tools and setups.

Efficiency and Reduced Downtime: Quick tool changes are a hallmark of interchangeable head tool sets. This feature significantly reduces downtime between machining operations, resulting in increased overall production efficiency. Manufacturers can minimize idle periods and maintain a steady workflow, ultimately improving productivity.

Cost Savings: By streamlining processes and reducing the number of tools required, interchangeable head turning tool sets can lead to significant cost savings. Manufacturers can expect reduced tooling expenses, fewer tool changeovers, and lower labor costs related to setup and adjustments.

Precision and Consistency: The precision of interchangeable head tools ensures consistent and high-quality machining results. Manufacturers can achieve tight tolerances and produce precision components with minimal variation, which is particularly important for industries like aerospace and medical devices.

Adaptability: In today's dynamic manufacturing landscape, adaptability is essential. Interchangeable head tool sets allow manufacturers to quickly adjust to changing production requirements. Whether it involves transitioning from one job to another or accommodating design modifications, these sets provide flexibility and agility.

Leveraging Interchangeable Head Turning Tool Sets for Process Improvement:

Select the Right Tool Set: Begin by carefully evaluating the machining needs of your specific applications. Choose interchangeable head turning tool sets that offer the appropriate types of inserts, toolholder designs, and cutting geometries that align with your machining requirements.

Optimize Tool Change Procedures: Implement efficient tool change procedures to make the most of the quick-change capabilities of the tool set. Minimize setup times and ensure that operators are well-trained in the proper tool change process.

Implement Lean Practices: Maximize the benefits of interchangeable head tool sets by incorporating lean manufacturing principles. Reduce setup times further, minimize spare tool inventory, and optimize tool changeovers to eliminate waste and improve overall efficiency.

Embrace Advanced Coatings: Many modern inserts come with specialized coatings that enhance performance by reducing friction and increasing wear resistance. Evaluate the most suitable coatings for your machining needs to extend tool life and maintain consistent quality.

Continuous Monitoring and Maintenance: Regularly monitor tool wear and performance to schedule maintenance and replacements proactively. Well-maintained tools are crucial for achieving optimal results and minimizing unexpected downtime.

Operator Training: Invest in training for your machining personnel to ensure they understand the capabilities and best practices associated with interchangeable head turning tool sets. Skilled operators can maximize the tool set's potential and troubleshoot issues effectively.

interchangeable head turning tool sets offer numerous advantages in precision machining, including versatility, efficiency, cost savings, precision, and adaptability. Manufacturers can optimize their production processes by selecting the right tool set, optimizing tool and insert choices, embracing lean practices, and investing in training and maintenance. Leveraging this technology can result in improved productivity, reduced costs, and enhanced machining quality, making it a valuable asset in the manufacturing industry.

Advantages of Interchangeable Head Turning Tool Sets:

Versatility: Interchangeable head turning tool sets are designed with a variety of cutting inserts and toolholders, making them versatile tools for machining. These sets allow manufacturers to perform different machining operations with a single tool set, reducing the need for multiple tools and setups.

Efficiency: The quick-change feature of interchangeable head tool sets significantly reduces downtime between machining operations. This results in improved overall production efficiency, as manufacturers can minimize idle periods and maintain a continuous workflow.

Cost Savings: Streamlining processes and reducing the number of tools required can lead to cost savings. Manufacturers can expect reduced tooling expenses, fewer tool changeovers, and lower labor costs associated with setup and adjustments.

Precision and Consistency: Interchangeable head tools are engineered for precision, ensuring consistent and high-quality machining results. This is critical for industries where tight tolerances and precise components are essential.

Adaptability: In today's dynamic manufacturing landscape, adaptability is crucial. Interchangeable head tool sets enable manufacturers to quickly adjust to changing production requirements, whether transitioning between jobs or accommodating design modifications.

Considerations for Incorporating Interchangeable Head Turning Tool Sets:

Tool Selection: Begin by carefully assessing the specific machining needs of your applications. Choose an interchangeable head turning tool set that offers the appropriate types of inserts, toolholder designs, and cutting geometries that align with your machining requirements.

Tool Change Procedures: Implement efficient tool change procedures to make the most of the quick-change capabilities of the tool set. Minimize setup times and ensure that operators are well-trained in the proper tool change process.

Lean Manufacturing: To maximize the benefits of interchangeable head tool sets, consider incorporating lean manufacturing principles into your operations. This involves reducing setup times further, minimizing spare tool inventory, and optimizing tool changeovers to eliminate waste and improve overall efficiency.

Advanced Coatings: Many modern inserts come with specialized coatings that enhance performance by reducing friction and increasing wear resistance. Evaluate the most suitable coatings for your machining needs to extend tool life and maintain consistent quality.

Monitoring and Maintenance: Regularly monitor tool wear and performance to schedule maintenance and replacements proactively. Well-maintained tools are crucial for achieving optimal results and minimizing unexpected downtime.

Operator Training: Invest in training for your machining personnel to ensure they understand the capabilities and best practices associated with interchangeable head turning tool sets. Skilled operators can maximize the tool set's potential and troubleshoot issues effectively.

interchangeable head turning tool sets offer significant advantages in machining, including versatility, efficiency, cost savings, precision, and adaptability. Manufacturers should carefully consider their specific machining needs when selecting a tool set and ensure that they optimize tool change procedures, incorporate lean manufacturing practices, and invest in training and maintenance to leverage the full potential of this technology. Implementing interchangeable head turning tool sets can result in improved productivity, reduced costs, and enhanced machining quality, making them a valuable asset in the manufacturing industry.