View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More

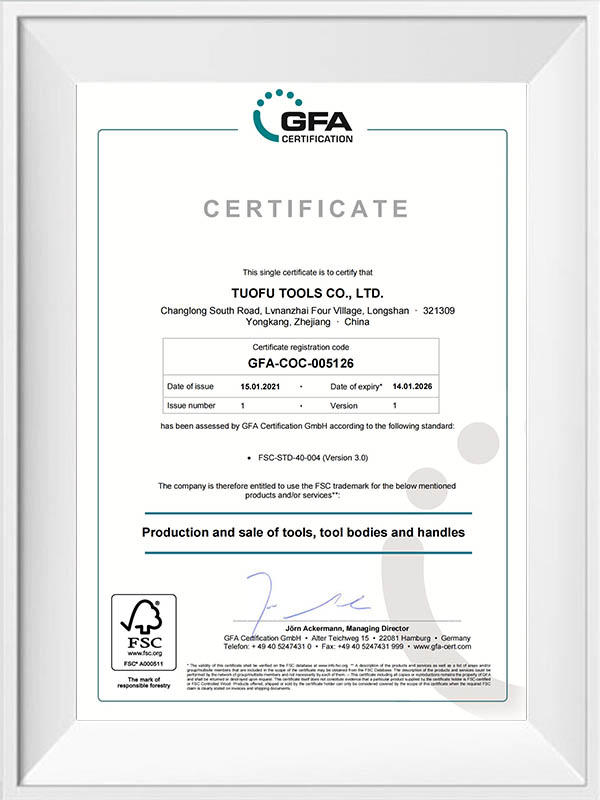

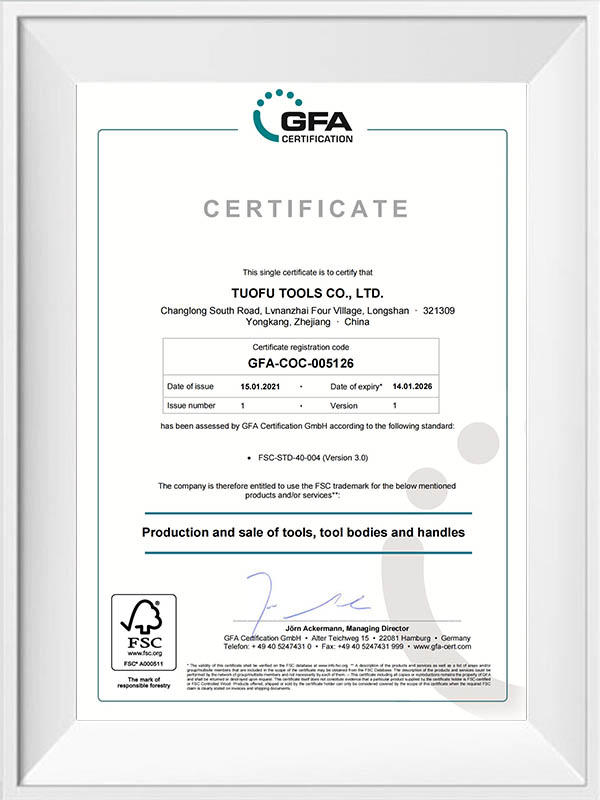

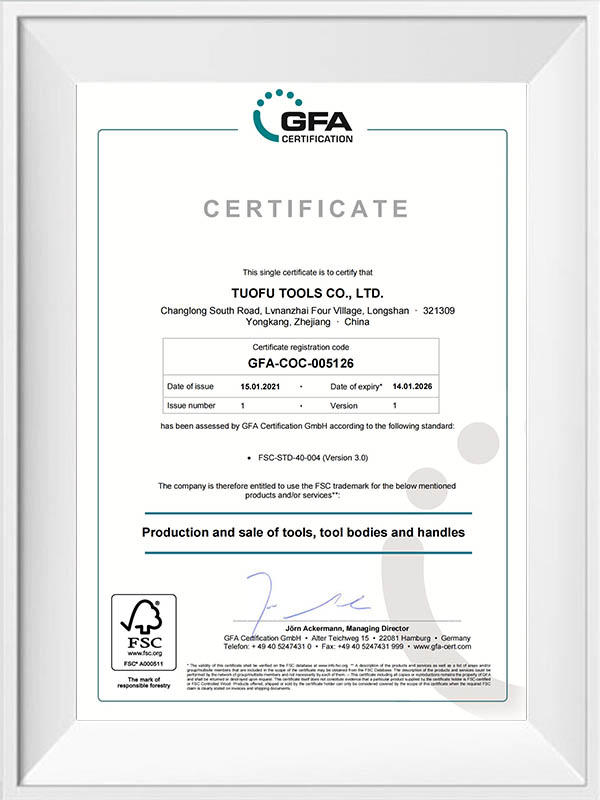

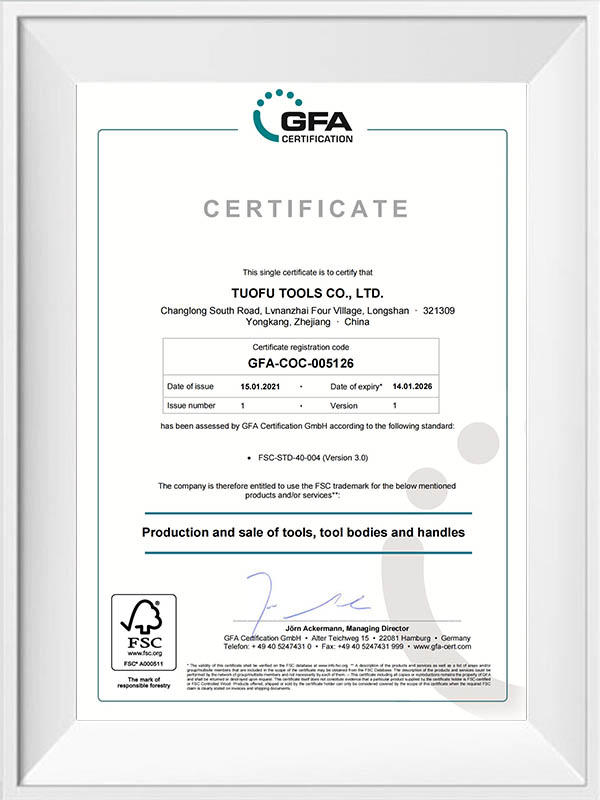

Zhejiang Yongkang Tuofu Tools Co., Ltd. is located in Yongkang, the famous hardware capital in China. It is an enterprise specializing in the production of medium and high-end hardware tools. After years of development, the company has strong independent design and development capabilities, and has the annual production capacity of 20 million pieces of various woodworking tools and carving tools. The products are mainly exported to Europe, Germany, the United States, Russia and Japan. and other countries and regions. The product quality is stable, the benefits are remarkable, and are well received by users. The company always strictly implements the requirements of the GS quality system standard, and always adheres to the principle of "quality first" in production. After 20 years of hard work, the product quality has reached the domestic advanced level.

Woodturning is a skill that requires not only creativity but also the right tool...

View MoreIn recent years, woodworking has evolved from a traditional craft into a popular...

View MoreHaving the right tools is essential for precision and ease. Among the wide range...

View MoreHaving the right tools is crucial for achieving quality results. An increasingly...

View MoreWoodcarving is an intricate craft that requires precision, skill, and the right ...

View MoreIn the woodworking industry, the use of specialized tools has been pivotal in creating unique and high-quality products. These tools are designed to tackle specific challenges, improve efficiency, and push the boundaries of design and craftsmanship. While traditional woodworking tools are essential, innovative tools may provide a variety of benefits:

1. Precision and Consistency: Specialized tools are engineered for specific tasks, ensuring precise and consistent results. For example, a miter turning tool designed to work with willow wood can help artisans create complex and precise miter joints with ease.

2. Material Optimization: Specialized tools are often designed to maximize the use of specific materials. In the case of willow wood, which is known for its flexibility, a specialized tool can help woodworkers utilize its unique properties to create intricate designs that would be challenging with conventional tools.

3. Improved Efficiency: Specialized tools can streamline the woodworking process, reducing production times and labor costs. This can lead to increased productivity and potentially lower prices for consumers.

4. Creativity and Innovation: Innovative tools can inspire woodworkers to experiment with new designs and techniques. The introduction of a novel tool like the "Water Bent Willow 25mm Miter Turning Tool" could open up new possibilities for artistic expression in woodworking.

5. Market Differentiation: Using specialized tools can set woodworking businesses apart in a competitive market. Unique and high-quality products often command higher prices and attract a discerning customer base.

6. Sustainability: Specialized tools can contribute to sustainable woodworking practices by optimizing material usage and reducing waste.

Selecting the right miter turning tool for water bent willow applications is crucial to ensure the efficiency and quality of the bending process. Willow wood is known for its flexibility and ease of bending when properly conditioned with water. To achieve precise and consistent bends in willow wood, a 25mm miter turning tool plays a vital role.

1. Material Quality:

The material quality of the miter turning tool is essential. It should be made of high-quality steel or alloy to withstand the stresses and heat generated during the bending process. Poor-quality tools may warp or deform, leading to inconsistent bends.

2. Blade Sharpness:

The sharpness of the tool's blades is critical for clean and smooth cuts. Dull blades can tear the wood fibers, resulting in a rough finish and weakening the bent sections.

3. Angle Adjustability:

A 25mm miter turning tool should offer adjustable angles to accommodate various bending requirements. Precise angle adjustments allow for the creation of intricate and custom bends in willow wood.

4. Compatibility with Willow Thickness:

Ensure that the tool is suitable for the thickness of willow wood you intend to bend. Different tools may be required for thinner or thicker willow stock.

5. Heat Resistance:

Willow bending often involves applying heat to the wood to make it more pliable. The miter turning tool should be heat-resistant to withstand this process without damage.

6. Ergonomics and Comfort:

Consider the ergonomics of the tool's handle and grip. Comfortable handling reduces fatigue during prolonged use and helps maintain precision in bending.

7. Durability and Longevity:

Evaluate the tool's durability and longevity. It should withstand frequent use and maintain its performance over time.

8. Safety Features:

Safety should be a priority. Look for tools with safety features like blade guards and locking mechanisms to prevent accidents during operation.

9. Compatibility with Water Bending Process:

Ensure that the miter turning tool is compatible with the water bending process. It should work seamlessly with the wood's moisture content and not corrode or degrade due to exposure to water.

10. Maintenance Requirements:

Consider the maintenance needs of the tool. Tools that are easy to clean and maintain will have a longer service life and provide consistent results.

Impact on Bending Quality and Efficiency:

Selecting the right 25mm miter turning tool for water bent willow applications significantly impacts both the quality and efficiency of the bending process. A well-chosen tool will result in:

Precision: The tool's angle adjustability and sharp blades enable precise bends, leading to consistent and aesthetically pleasing results.

Efficiency: A high-quality tool can make the bending process more efficient by reducing the need for rework and adjustments. This saves time and resources.

Safety: Tools with safety features enhance workplace safety and reduce the risk of accidents, ensuring the well-being of artisans and workers.

Durability: Durable tools reduce the frequency of replacements, saving on equipment costs in the long run.

when selecting a 25mm miter turning tool for water bent willow applications, consider factors like material quality, blade sharpness, angle adjustability, and compatibility with the bending process. A well-chosen tool not only ensures a higher quality of bends but also enhances the overall efficiency of the bending process, ultimately leading to better products and reduced production costs.