View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More  View More

View More

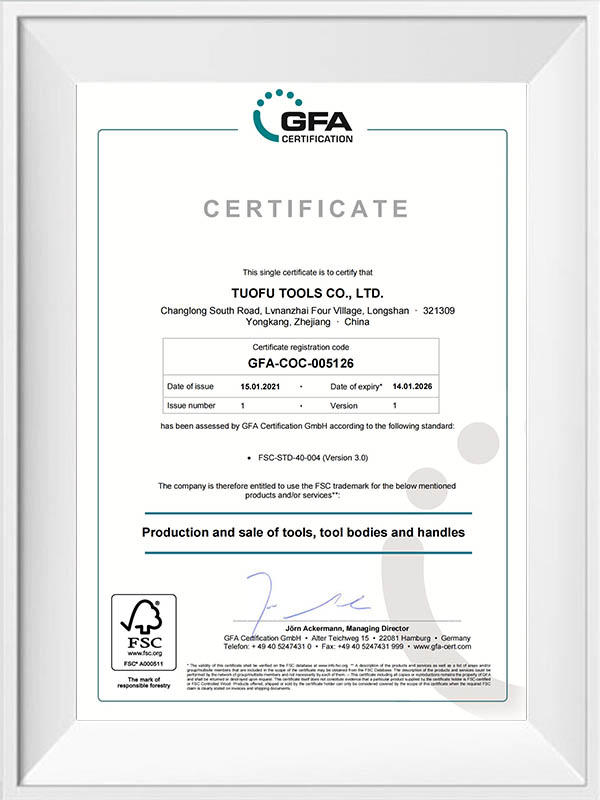

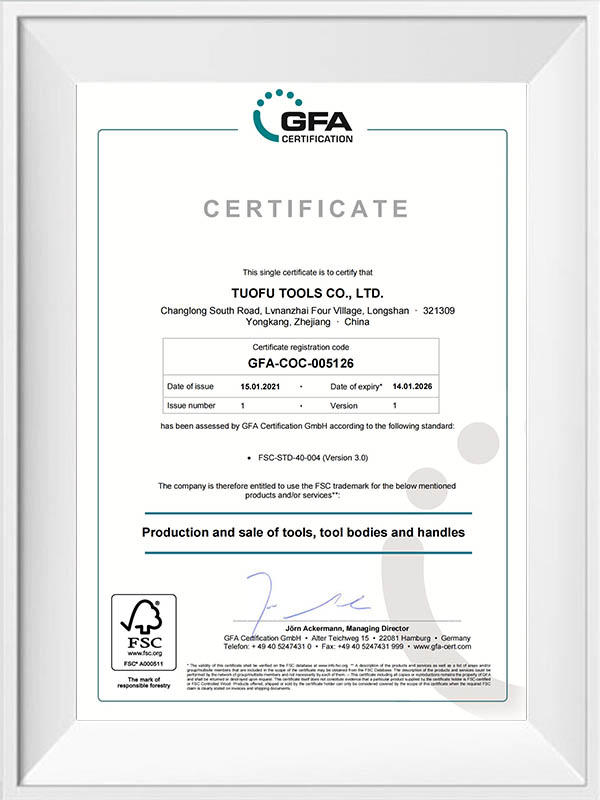

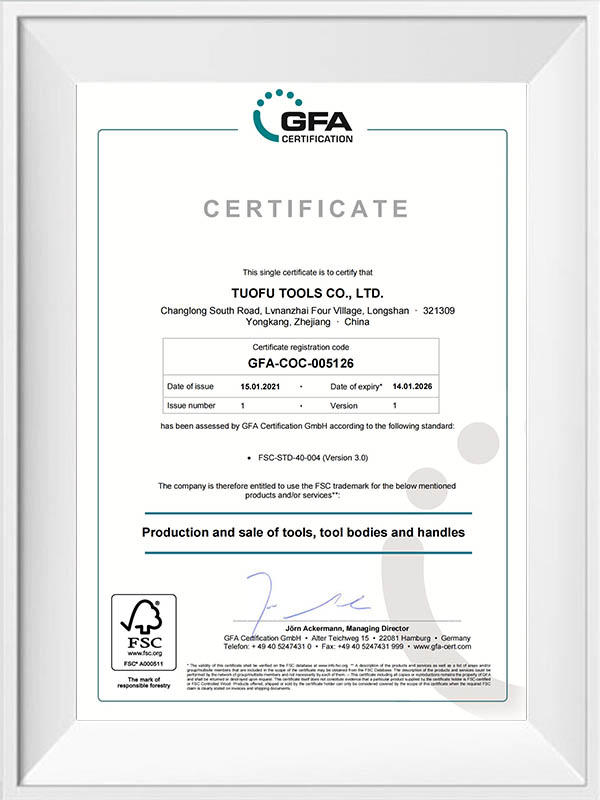

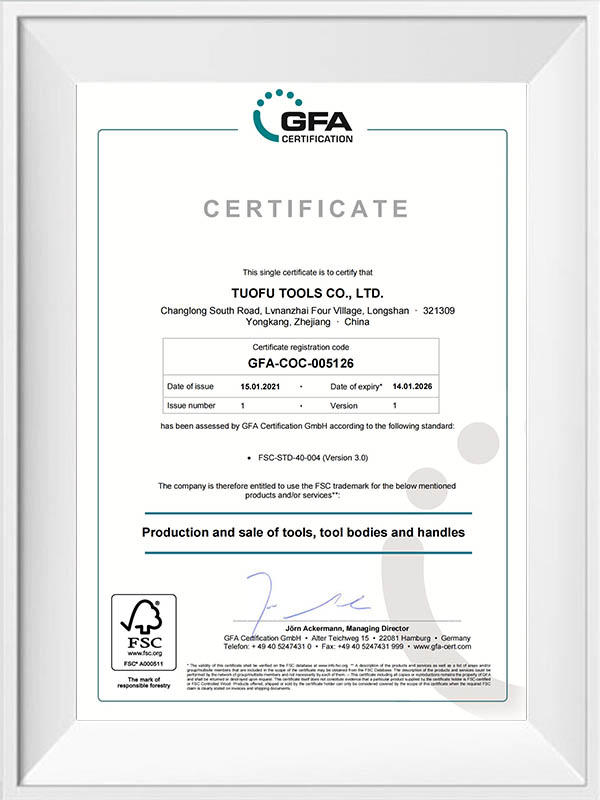

Zhejiang Yongkang Tuofu Tools Co., Ltd. is located in Yongkang, the famous hardware capital in China. It is an enterprise specializing in the production of medium and high-end hardware tools. After years of development, the company has strong independent design and development capabilities, and has the annual production capacity of 20 million pieces of various woodworking tools and carving tools. The products are mainly exported to Europe, Germany, the United States, Russia and Japan. and other countries and regions. The product quality is stable, the benefits are remarkable, and are well received by users. The company always strictly implements the requirements of the GS quality system standard, and always adheres to the principle of "quality first" in production. After 20 years of hard work, the product quality has reached the domestic advanced level.

Woodturning is a skill that requires not only creativity but also the right tool...

View MoreIn recent years, woodworking has evolved from a traditional craft into a popular...

View MoreHaving the right tools is essential for precision and ease. Among the wide range...

View MoreHaving the right tools is crucial for achieving quality results. An increasingly...

View MoreWoodcarving is an intricate craft that requires precision, skill, and the right ...

View MoreConsiderations for Selecting and Using Bowl Chisel Turning Tools:

Chisel Type and Size: The choice of chisel type and size depends on the specific design and dimensions of the wooden bowl. Smaller bowls may require smaller, delicate chisels, while larger bowls demand larger and more robust tools. Woodworkers should match the chisel size to the project at hand.

Chisel Bevel Angle: Bowl chisels come with different bevel angles, which affect how the tool interacts with the wood. A steeper bevel angle is more aggressive, while a shallower angle provides finer control. Woodworkers should select the appropriate bevel angle based on their skill level and the desired finish.

Material of Chisel: Bowl chisel turning tools are commonly made from high-speed steel (HSS) or carbon steel. HSS chisels are known for their durability and edge retention, making them suitable for heavy-duty turning. Carbon steel chisels can provide excellent results with proper sharpening and maintenance.

Handle Design and Comfort: The handle design and comfort are crucial for extended use. Woodworkers should choose chisels with ergonomic handles that provide a secure and comfortable grip. This ensures precise control and reduces the risk of hand fatigue.

Sharpening and Maintenance: Regular sharpening is essential for maintaining the edge of bowl chisel turning tools. Woodworkers should have the necessary sharpening equipment and skills to keep their chisels in optimal condition.

Safety Precautions: Woodworking, especially turning bowls, involves inherent risks. Woodworkers must use safety equipment, such as face shields and dust collection systems, to protect themselves from flying wood chips and dust. Additionally, proper technique and safe handling of chisels are vital to prevent accidents.

Contribution to Wooden Bowl Craftsmanship:

Precision Shaping: Bowl chisel turning tools enable woodworkers to precisely shape and hollow out wooden bowls. The fine cutting edge allows for intricate designs and smooth, even surfaces, resulting in aesthetically pleasing bowls.

Control and Artistry: These tools provide woodworkers with the control necessary to bring their creative visions to life. Whether it's crafting delicate fluted patterns or sculpting intricate details, bowl chisel turning tools empower artisans to express their artistry.

Efficiency: Bowl chisels are designed to efficiently remove material while minimizing waste. Their sharp cutting edges and controlled cutting actions ensure that woodworkers can shape bowls with precision and material efficiency.

Quality Finish: With the right technique and well-maintained chisels, woodworkers can achieve a high-quality finish on wooden bowls. This is essential for showcasing the natural beauty of the wood and ensuring that the final product is both functional and visually appealing.

Versatility: Bowl chisel turning tools are versatile and can be used for various bowl designs, from shallow decorative bowls to deep salad bowls. This adaptability makes them suitable for a wide range of projects and styles.

bowl chisel turning tools are indispensable instruments in the woodworking industry, particularly for those engaged in crafting wooden bowls and vessels. Woodworkers should carefully consider factors such as chisel type, size, bevel angle, and handle design when selecting these tools. When used skillfully and safely, these tools contribute to precision shaping, artistic expression, efficiency, and high-quality finishes, resulting in finely crafted wooden bowls that showcase the craftsmanship of the woodworker.

Spindle Roughing Gouge: This tool is used to quickly shape the wood into a cylinder and remove excess material. It's an excellent choice for beginners as it helps them get a feel for the lathe.

Spindle Gouge: A spindle gouge is versatile and can be used for shaping details on spindles, such as coves and beads. It's an essential tool for creating intricate designs.

Parting Tool: This tool is used to create parting cuts, separate the workpiece from the lathe, and define tenons or other features. It's essential for safely removing the workpiece from the lathe.

Skew Chisel: The skew chisel is a versatile tool for both spindle and bowl turning. It's used for making clean cuts and creating smooth surfaces. However, it can be challenging to master, so beginners may need some practice.

Bowl Gouge: As the name suggests, a bowl gouge is specifically designed for turning bowls. It's a deep-fluted gouge that helps hollow out the interior of bowls efficiently.

Scraper: A scraper is used to refine the surface of the workpiece and remove tool marks. It's particularly useful for finishing cuts on both spindle and bowl projects.

Chuck and Chucking Tools: Chucks are used to secure the workpiece to the lathe, making it easier to work on the reverse side. Chucking tools, like jaws and worm screws, are necessary for securely mounting the wood.

Sharpening Equipment: Properly maintaining sharp cutting edges is crucial in woodturning. Invest in a sharpening system, such as a bench grinder or a sharpening jig, to keep your tools sharp.

Safety Gear: Safety should be a top priority. Wear a face shield, dust mask, and hearing protection when woodturning to protect yourself from flying wood chips and dust.

Instruction and Education: Learning from experienced woodturners through classes, workshops, or online tutorials is invaluable for beginners. It helps you develop skills and understand the nuances of woodturning.