Whitewood bowl chisel turning tool

Wood turning chisel

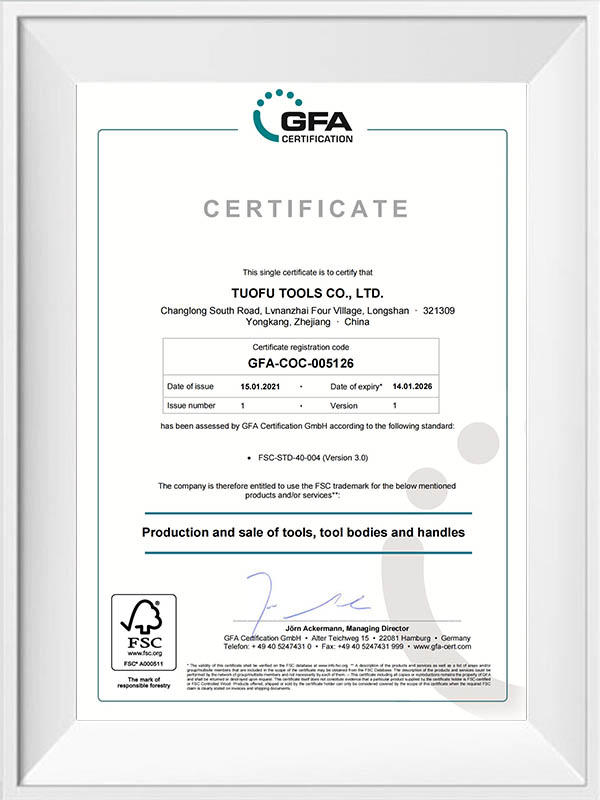

Zhejiang Yongkang Tuofu Tools Co., Ltd. is located in Yongkang, the famous hardware capital in China. It is an enterprise specializing in the production of medium and high-end hardware tools. After years of development, the company has strong independent design and development capabilities, and has the annual production capacity of 20 million pieces of various woodworking tools and carving tools. The products are mainly exported to Europe, Germany, the United States, Russia and Japan. and other countries and regions. The product quality is stable, the benefits are remarkable, and are well received by users.

The company always strictly implements the requirements of the GS quality system standard, and always adheres to the principle of "quality first" in production. After 20 years of hard work, the product quality has reached the domestic advanced level.

Woodturning is a skill that requires not only creativity but also the right tool...

View MoreIn recent years, woodworking has evolved from a traditional craft into a popular...

View MoreHaving the right tools is essential for precision and ease. Among the wide range...

View MoreHaving the right tools is crucial for achieving quality results. An increasingly...

View MoreChisel Material and Coatings:

The material from which the turning chisels are made plays a significant role. Common materials include high-speed steel (HSS), carbide, and cobalt. Carbide chisels are known for their durability and high cutting speeds.

Coatings, such as titanium nitride (TiN) or diamond-like carbon (DLC), can enhance the chisel's performance by reducing friction and increasing tool life.

Chisel Geometry:

The geometry of a chisel, including its rake angle, clearance angle, and tip shape, affects how efficiently it cuts and how smoothly it finishes the workpiece surface.

Properly ground chisels with the right angles reduce heat generation and minimize tool wear.

Chisel Size and Shape:

Choosing the appropriate chisel size and shape depends on the specific machining task. Smaller chisels are suitable for intricate work, while larger ones are better for heavy-duty tasks.

Specialized chisels, such as threading tools or parting tools, are designed for specific operations.

Cutting Speed and Feed Rate:

The type of turning chisel set selected should align with the cutting speeds and feed rates recommended for the material being machined. A mismatch can lead to tool wear, poor finish quality, or even damage to the workpiece.

Machine Rigidity and Stability:

The choice of chisels should be considered in conjunction with the capabilities of the lathe or CNC machine. A stable and rigid machine is essential for achieving precision in machining.

Workpiece Material:

Different materials, such as aluminum, steel, or exotic alloys, require specific types of turning chisels. Harder materials may necessitate carbide chisels, while softer ones can be worked with HSS chisels.

Operator Skill and Experience:

Skilled operators can often maximize the performance of a turning chisel set through proper tool selection, setup, and machining techniques.

1. Chisel Types and Sizes:

Consideration: Turning chisels come in various types, including gouges, scrapers, and parting tools. Each type has a specific purpose.

Optimization: Choose chisels that match your project requirements. Gouges are versatile for shaping, while scrapers are excellent for smoothing. Ensure you have a variety of sizes to handle different tasks effectively.

2. Quality of Steel:

Consideration: The quality of steel in chisels impacts their durability and sharpness retention.

Optimization: Invest in high-quality chisels made from high-speed steel (HSS) or carbon steel for longevity and ease of sharpening.

3. Handle Comfort and Design:

Consideration: Comfortable handles reduce fatigue during extended use.

Optimization: Choose chisels with ergonomic handles that provide a secure grip and minimize hand strain.

4. Sharpening and Maintenance:

Consideration: Dull chisels can lead to accidents and subpar results.

Optimization: Learn proper sharpening techniques and maintain chisels regularly. Sharpening jigs and honing guides can help maintain consistent bevel angles.

5. Safety Measures:

Consideration: Woodturning can be dangerous if not done safely.

Optimization: Always wear appropriate safety gear, including eye protection and dust masks. Learn safe lathe operation techniques and turning practices.

6. Cutting Techniques:

Consideration: Proper cutting techniques result in clean and precise work.

Optimization: Practice controlled cuts and maintain a stable tool rest position to minimize chatter and vibrations. Always approach the wood from the right angle.

7. Project Material:

Consideration: Different wood types have varying hardness levels and grain patterns.

Optimization: Adjust your chisel selection and cutting techniques based on the wood's characteristics. Softer woods may require less aggressive tools and cuts.

8. Project Planning:

Consideration: Planning ahead can save time and materials.

Optimization: Sketch out your turning project, including dimensions and design details, before starting. This helps you select the appropriate chisels and reduce mistakes.

9. Speed and Lathe Settings:

Consideration: The lathe speed and settings affect the quality of your turning work.

Optimization: Adjust lathe speed and tool rest position based on the project and chisel type. Higher speeds are generally used for finer details.

10. Practice and Experience:

Consideration: Skill and experience greatly influence woodturning outcomes.

Optimization: Continuously practice and take on diverse projects to improve your turning skills and understanding of chisel use.