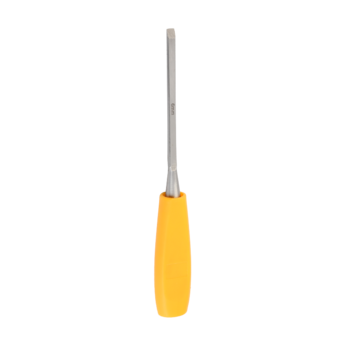

Sales turning chisel set Factory, turning chisel set Factory Manufacturer, turning chisel set Factory in China

In the world of woodworking, the tools that designers choose are pivotal to the creation of exceptional pieces. Among these tools, the Turning Chisel Set Factory stands as the foundation for quality craftsmanship. In this article, we will delve into the practical aspects and advantages of incorporating turning chisel sets from the factory perspective, offering a unique insight into the craftsmanship behind these essential woodworking tools.

The Role of the Turning Chisel Set Factory

The Turning Chisel Set Factory plays a central role in the production of high-quality tools designed for woodturning. These factories are dedicated to crafting chisels that meet the rigorous standards demanded by designers and craftsmen. The meticulous processes employed in these factories ensure that each turning chisel set is not only functional but also durable, providing a reliable toolkit for woodworking professionals.

Precision in Manufacturing

Precision is a hallmark of any well-crafted tool, and the Turning Chisel Set Factory prioritizes precision in every step of the manufacturing process. From the selection of raw materials to the final sharpening of the blades, each stage is executed with meticulous attention to detail. This commitment to precision results in turning chisels that consistently deliver accurate and clean cuts, meeting the expectations of designers who demand excellence in their work.

Craftsmanship at Scale

Craftsmanship is not solely reserved for individual artisans; it extends to the factories that produce the tools used by designers worldwide. The Turning Chisel Set Factory embodies craftsmanship at scale, where skilled workers employ their expertise to create tools that embody quality and reliability. This factory-driven craftsmanship ensures that designers have access to turning chisels that uphold the highest standards, allowing them to bring their creative visions to life.

Customization for Varied Needs

The diversity of woodworking projects requires turning chisel sets that cater to varied needs. The Turning Chisel Set Factory recognizes this demand and often offers customization options to meet the specific requirements of designers. Whether it's the choice of materials, handle designs, or blade configurations, the ability to customize turning chisel sets ensures that designers can select tools tailored to their unique preferences and the demands of their projects.

Efficiency in Production

Efficiency in production is a key aspect of the Turning Chisel Set Factory. Implementing streamlined processes, advanced machinery, and skilled labor, these factories can produce turning chisel sets with consistency and precision. The combination of efficient production methods and a commitment to quality results in tools that not only meet the demands of designers but also contribute to the overall efficiency of the woodworking process.

Quality Materials for Enduring Tools

The foundation of any turning chisel set lies in the quality of materials used in its construction. The Turning Chisel Set Factory selects premium materials that not only withstand the rigors of woodworking but also contribute to the longevity of the tools. High-quality steel for the blades and durable handles crafted from reliable materials ensure that the turning chisels produced by the factory are built to endure the demands of professional use.

Innovation in Design

While avoiding hyperbole, it's essential to acknowledge the role of innovation in the Turning Chisel Set Factory. Innovations in design, whether in handle ergonomics, blade configurations, or manufacturing processes, contribute to the continuous improvement of turning chisel sets. The focus on innovation ensures that designers have access to tools that not only meet current standards but also anticipate the evolving needs of the woodworking industry.

Consistency Across the Product Line

Consistency is a hallmark of a reputable Turning Chisel Set Factory. Whether a designer purchases a basic set or opts for a more specialized collection, they can expect consistency in the quality of materials, craftsmanship, and performance across the entire product line. This uniformity instills confidence in designers, knowing that each turning chisel in the set meets the same high standards upheld by the factory.

Sustainable Practices in Manufacturing

In the modern era, sustainability is a key consideration in manufacturing processes. The Turning Chisel Set Factory recognizes the importance of sustainability and endeavors to incorporate eco-friendly practices where possible. From responsible sourcing of materials to waste reduction initiatives, these factories align with the growing awareness of environmental impact, providing designers with tools crafted with a commitment to sustainability.

Factory Insights: From Raw Materials to Finished Product

A closer look at the journey of a turning chisel set from the factory offers valuable insights into the meticulous processes involved. The selection of raw materials, precision machining of components, assembly of handles, blade sharpening, and quality control measures are all integral steps in ensuring that each turning chisel set leaving the factory meets the highest standards. This attention to detail is a testament to the dedication of the factory in delivering tools that exceed expectations.

Meeting Industry Standards

The Turning Chisel Set Factory adheres to industry standards and regulations, ensuring that the tools produced meet or exceed the expectations of woodworking professionals. From metallurgical standards for blade quality to ergonomic guidelines for handle design, the factory places a strong emphasis on compliance, resulting in turning chisels that designers can trust for their reliability, safety, and performance.

Collaboration with Designers for Continuous Improvement

The relationship between the Turning Chisel Set Factory and designers is symbiotic. While designers rely on the factory for high-quality tools, the factory, in turn, values feedback from designers to drive continuous improvement. This collaborative approach ensures that turning chisel sets evolve to meet the ever-changing demands of woodworking, fostering a dynamic partnership between those who craft the tools and those who use them.

Conclusion

In conclusion, the Turning Chisel Set Factory serves as the backbone of quality craftsmanship in woodworking. Through precision manufacturing, efficient production, the use of quality materials, innovation in design, and a commitment to sustainability, these factories play a vital role in providing designers with the tools they need to bring their creative visions to life. The collaboration between designers and the Turning Chisel Set Factory represents a synergy that drives continuous improvement, ensuring that turning chisel sets remain essential companions for designers in their pursuit of excellence in woodworking.

English

English 中文简体

中文简体